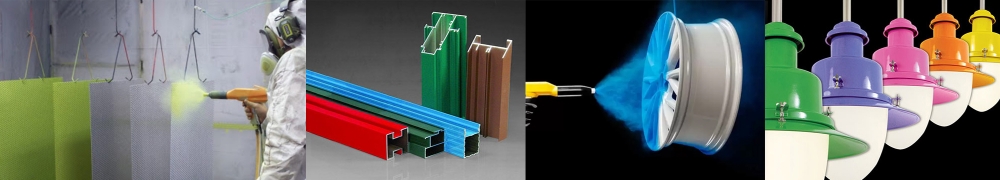

Electrostatic Powder Coating

Electrostatic powder coating is a solvent-free production method that uses electrically charged particles to paint a part more efficiently. Powder paint, which is used as functional and decorative, is applied in a dry and free flowing state. The biggest difference between powder paint and wet paint is that powder paint does not require the use of solvents to enclose the filler, pigments and resin.

Powder paint, which is generally electrostatically applied, is baked for a certain time at 120 to 240 degrees to obtain a hard and smooth (rough if desired) surface.

We can paint metal parts of different types and sizes with electrostatic powder paint in our own production area. By using our surface treatment lines, which is one of the facilities of our production facility, we can increase the appearance of the electrostatic powder paints and the life of the parts to higher levels.

In our production facility, there is a double chambered and filtered powder paint booth with a conveyor system, a drying oven with a conveyor, 3 powder paint guns, hangers, hooks and other assistive equipment.

English »

English »